Benefits of Using Fume Hoods in Labs

The first duty and choice of the scientific researcher are to use the appropriate personal protective gear to create a barrier of protection between them and chemical risks (PPE). The laboratory fume hood, on the other hand, offers a more substantial and measurable mechanical, atmospheric, and safety barrier against dangerous vapours, powders, and spills. One should take great care of the fume hood Malaysia and consider it a flexible partner in hazard mitigation rather than taking it for granted since it appears to have been a fixture in laboratories since the dawn of time. As a result, there are crucial individual parts that must work correctly and consistently as a unit and that can be improved or altered to improve or restore performance. Additionally, there are aspects of hood design and construction that are especially suited to certain chemical operations that differ in scope and function.

When it becomes obvious that they will need to make room for new laboratory space or personnel changes, researchers and lab managers should make plans for upgrading or replacing hood systems. When the nature of the entire application changes to a new type and degree of chemical processes, hood system replacements and overhauls become especially necessary.

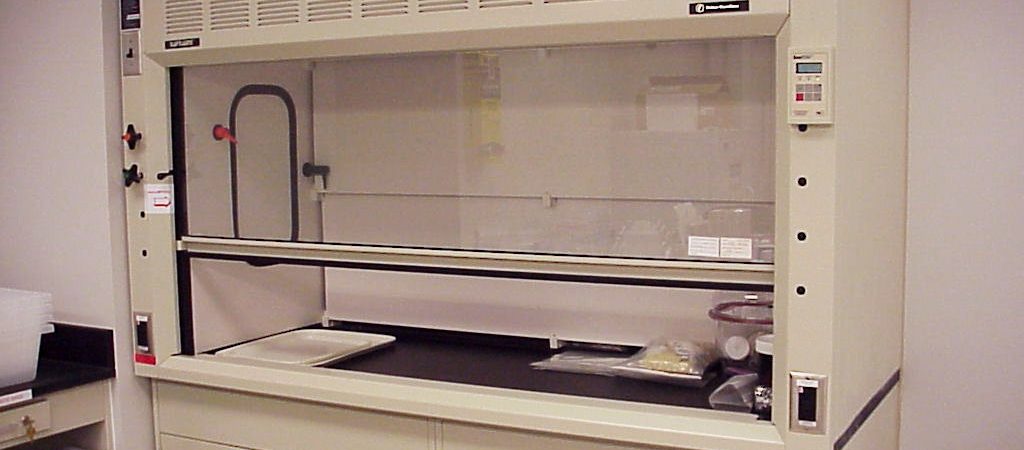

Work Surfaces and Cabinets

A fume hood is essentially an elevated box with various limitations. The work cabinet has to be capable of maintaining a safe perpendicular airflow or face velocity, at the hypothetical plane that delineates the interface between the worker and the working surface when the sash is lifted (or broadened). In order to contain vapours before they are ducted and vented, the volumetric flow of air that is required inside the hood is correlated to face velocity. Some modern high-performance cabinets may now operate safely with face velocities as low as 40 fpm, resulting in significant energy and cost savings by limiting volumetric flow. Face velocities at 50% sash height frequently exceed 100 fpm, despite this.

Safety Monitoring

Following the guidelines for routine re-certification set by chemical safety officers strictly is the first line of defence. By doing so, the hood’s performance will be up to par, and its lifespan will be increased. Modern monitoring equipment can measure the flow of clean ambient air using sidewall sensors and measure the velocity of exhaust air leaving the hood with inline or probe sensors. Visual, aural, and remote app-based alarms alert users when the face or duct velocities are compromised. Touchscreens that are responsive to gloved fingers can be used to modify parameters and thresholds, and performance data can be recorded and evaluated in accordance with both ANSI/NFPA standards and GLP/GMP guidelines.

Blowers and Ducting

To effectively transfer vapours out of the hood and propel them through building systems to the outside, a safe hood must maintain a threshold duct velocity similar to the face velocity at the plane of the sash. To maximize the airflow suited for the size and kind of hood, a synergy between hood capacity, blower size, and ducting arrangement is required. A powerful blower may potentially overload the duct system and cause turbulence within the cabinet airflow, impairing both face and duct velocities. A weak blower exhausting a big cabinet will not sufficiently evacuate vapours.